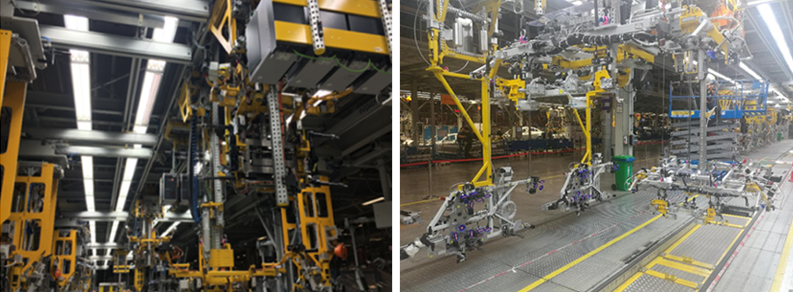

Project: Daqing Volvo machinery installation project

Time: from 2017 to now

End user: Geely Asia Pacific Volvo Daqing plant

Project Description:

Since July 2017, our company has successively undertaken the mechanical installation projects of Daqing Volvo plant, and mastered the mechanical process and quality standards of Volvo. Under the tight construction period, we still ensured the construction period and quality according to the nodes. This project includes mechanical installation of fixture and other production line equipment, robot positioning, steel structure platform installation, water and gas pipeline installation, etc.

|

Time |

Entry name |

|

2020.09 |

Project Name: Daqing Volvo manual operation training Island mechanical installation project |

|

2018.09 |

Zhejiang Luqiao Volvo looks at K431 side wall main line mechanical installation project |

|

2018.12 |

Daqing Volvo K431 four door and two cover mechanical installation project |

Project Name: body welding production line project of BMW Brilliance Tiexi factory

Final customer: BMW Brilliance Tiexi factory

Time: 2017 - present

Project Description:

Our company has successively undertaken the g2x / f39 finishing line transformation project of BMW Brilliance body welding workshop. The project includes the installation and debugging of eepos rail and fixture, and the transformation of the original steel structure through finite element analysis. Using the short stop time, remove the fixture and guide rail of the original production line, replace the new fixture and guide rail, and debug the whole line to meet the process requirements of the new model.

|

Time |

Entry name |

|

2017.07 |

BMW g2x MF finishing line reconstruction project |

|

2018.01 |

MF finishing line reconstruction project of BMW F39 |

Project: Changshu JLR body production line mechanical installation project

Time: from 2015 to now

End user: Changshu Chery Jaguar Land Rover factory

Project description

Since July 2015, our company has undertaken the mechanical installation of Changshu Jaguar Land Rover x260, x760, x540 and l551 projects. This project includes pre integration and overall wiring of production line, mechanical installation of fixture and other production line equipment, robot positioning, steel structure platform installation, water and gas pipeline installation, etc. From this, we have mastered the mechanical process and quality standard of JLR production line.

|

Time |

Entry name |

|

2015.07 |

Changshu Jaguar Land Rover x261 mechanical installation project |

|

2016.08 |

Changshu JLR x760 mechanical installation project |

|

2018.9 |

Changshu JLR x540 mechanical installation project |

|

2019.10 |

Changshu JLR l551 floor line reconstruction project |